Industry News and updates

July topic - Media selection and maintenance.

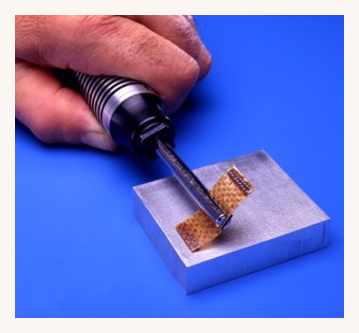

- Choose the right media type: Shot peening media comes in various materials, including cast steel, conditioned cut wire, glass beads, and ceramic beads. Each media type has specific properties that make it suitable for different workpiece materials and desired peening intensities. For example, conditioned cut wire shot is often favored for its durability and consistent spherical shape, while ceramic beads are preferred for softer metals like aluminum.

- Initial quality check: Before using any new batch of media, it should be thoroughly inspected to ensure it meets the required specifications for size, hardness, and shape. This initial check helps prevent the use of substandard media that could compromise the peening process or damage the workpiece.

- Choose the right media size. As a rule of thumb, you should choose the largest media you can achieve the required intensity and finish with. You must bear in mind the sizes of any radii or features that must be peened as well, and ensure that the shot will fit into those areas.

- Continuous classification: Shot peening machines should be equipped with media classification systems (screens, air classifiers, or spiral separators) to constantly remove undersized, broken, or deformed media particles. This ensures that only spherical shot impacts the workpiece, preventing potential surface damage.

- Media replenishment: As media degrades and is removed by the classification system, new media needs to be automatically added to the machine. Feeders ensure a continuous supply of fresh, high-quality media.

- Preventing contamination: Contamination by foreign particles (e.g., oil, grease, different media types, or machine parts) can significantly affect the peening process and workpiece quality. Regular checks for contamination, such as the vial test (ASTM D7393) for oil and grease, are crucial. Dedicated machines for specific media types (ferrous or non-ferrous) can prevent cross-contamination.

- Daily inspections: Operators should visually inspect the media daily for any signs of wear, degradation, or contamination.

- Weekly inspections: In addition to visual checks, media cleanliness should be assessed weekly using tests like ASTM D4940 to detect water-soluble contaminants. If using a recycling system, inspect it to ensure proper functioning.

- Monthly and quarterly inspections: Conduct thorough inspections of the media’s overall condition, including size distribution and wear, and replace any media showing significant degradation. Conduct system calibration to maintain media performance consistency.

- Annual evaluations: Perform a comprehensive evaluation of the media and the shot peening system annually. This includes checks for wear, contamination, and overall system efficiency. Replace worn components and media as necessary to ensure optimal performance.

- Documenting inspections: Maintaining detailed records of all media inspections, including observations, tests performed, and any corrective actions taken, is crucial for quality assurance and compliance with standards like NADCAP and AMS2430.

- Regular Inspection: Check for media degradation, such as fractures, rounding, or contamination.

- Cleanliness: Use separators and filters to remove fines, dust, and foreign materials.

- Sizing: Regularly screen to maintain consistent media size, ensuring uniform peening intensity.

- Storage: Keep media in a dry, clean environment to prevent moisture absorption and rust.

- Recycling: Reuse media within its lifespan, but replace it when it loses shape or effectiveness.

- Monitoring: Track media usage and performance to identify when replacements are needed.

2025 training workshops - held in Hereford. 13th - 16th October

Level 1 is the minimum requirement for shot peen operators and is the foundation for level 2. The level 1 course provides training in peening workshop operations & inspections.The content includes: Introduction to Peening; Intensity L1; Coverage & other inspections; Wheel Shot Peening Machines; Air peening machines & nozzles; Peening Media L1; Performing & Documentation

Level 2 is the minimum requirement for shot peen supervisors & technicians. Level 2 builds on the knowledge gained in level 1 to provide further capability in: Understanding Intensity & Saturation curves L2; Saturation curve exercises; Coverage L2; Engineering & Planning the process; Peening Reciprocating Engine Applications; Peening Media L2; Preparing for SP audit

Level 3 is the recommended standard for auditors, trainers & specifying engineers. Level 3 provides greater breadth and depth of knowledge to enhance the competence gained from the previous levels. Residual Stresses & their measurement; Fatigue & Stress Corrosion; Optimization of SP; SP Process Improvement; Alternative Peening Technologies I; Alternative Peening Technologies II; Undertaking a SP audit

FAA accepted Courses: All 3 courses offered during the workshop are FAA accepted. Participants who pass the optional examination receive a “Certificate of Achievement”, which has the related FAA acceptance number on it. The FAA acceptance gives comprehensive acceptance of capability for certified individuals. This third party approval of the training also conforms to European Continuing Airworthiness requirements.